Alleima® 20C is a hardened and tempered carbon steel characterized by:

-

High strength

-

High fatigue strength under bending and impact stress

-

Low level of non-metallic inclusions

-

Good wear resistance

Compressor valve steel in Alleima® 20C has excellent surface finish, good dimensional tolerances and good flatness.

Standards

- ASTM: 1095

- W.Nr.: 1.1274

- SS: 1870

Chemical composition (nominal)

| C | Si |

|---|---|

| 1.00 | 0.3 |

应用

阀片生产

为充分利用材料的性能,使用Sandvik Hiflex阀片钢带生产阀片时必须考虑其疲劳性能。

冲裁

山特维克建议冲裁时使用直边压床和刃口锋利的冲裁模具。磨损或受损的冲裁模具会导致阀片边缘产生难以在后期工序中消除的缺陷。冲模间隙推荐值为钢带厚度的4-10%。

我们通常建议使用工具钢AISID2或D4。如果板厚较厚、模具细长及圆角半径较小,我们则建议使用AISI M2钢。使用AISID2或D4、AISI M2钢模具的洛氏硬度值 (HRC) 都应为63左右。

应力消除

应力消除在冲裁和滚抛之间进行,旨在消除冲压应力。建议最高回火温度为350ºC (662ºF),保温时间30至60分钟。

滚抛

良好的滚抛可使边缘平整光滑,从而减少应力集中,同时也会增加表面残余压应力,从而显著提高疲劳性能。

Forms of supply

Strip steel is supplied in labelled coils, or on labelled plastic spools, depending on weight and size. The label details the steel grade, heat, lot and coil number, and nominal size, allowing full material traceability. Material is protected against rust with oil.

Coils are wrapped in paper and packed in wooden cases. For overseas shipment, coils are also sealed in a plastic bag containing silica gel. Net and gross weights are marked on the case. Customized properties, dimensions and tolerances can be supplied on request.

Thickness

Alleima® 20C comprevalve steel is supplied in standard thicknesses in accordance with the table.

| Thickness | Tolerance, ± | ||

|---|---|---|---|

| mm | in. | mm | in. |

| 0.152 | 0.006 | 0.005 | 0.00020 |

| 0.203 | 0.008 | 0.006 | 0.00024 |

| 0.254 | 0.010 | 0.007 | 0.00028 |

| 0.305 | 0.012 | 0.007 | 0.00028 |

| 0.381 | 0.015 | 0.008 | 0.00035 |

| 0.406 | 0.016 | 0.012 | 0.00047 |

| 0.457 | 0.018 | 0.012 | 0.00047 |

| 0.508 | 0.020 | 0.014 | 0.00055 |

| 0.559 | 0.022 | 0.020 | 0.00079 |

| 0.600 | 0.0236 | 0.020 | 0.00079 |

| 0.635 | 0.025 | 0.023 | 0.00091 |

| 0.762 | 0.030 | 0.023 | 0.00091 |

| 0.800 | 0.0315 | 0.027 | 0.00106 |

| 0.889 | 0.035 | 0.027 | 0.00106 |

| 1.000 | 0.0394 | 0.034 | 0.00134 |

Width

Strip in standard thicknesses is stocked in widths up to 350 mm (13.8 in.), ready for slitting to the required width.

Finishes

Edges

Edges are slit and deburred. Shaved edges can be supplied on request.

Flatness

Maximum out-of-flatness across and along the strip is 0.20% of the nominal strip width.

Surfaces

Material is delivered bright, fine polished.

Surface roughness

Maximum surface roughness values, cut-off 0.25 mm (.0098 inch), are shown in the table.

| Thickness | Ra | Rmax | |||

|---|---|---|---|---|---|

| mm | in. | µm | µin. | µm | µin. |

| <0.508 | <0.020 | 0.13 | 5.2 | 1.5 | 60 |

| >0.508 | >0.020 | 0.25 | 10.0 | 2.5 | 100 |

Surface defects

A small number of surface defects, such as pits and roll marks, with a depth or height of 2 µm (80 µin.) maximum is allowed for thicknesses up to 0.508 mm (0.020 in.) and 3 µm (120 µin.) maximum for thicker material. The maximum scratch depth allowed is as follows:

| Thickness | Max. allowed depth | ||

|---|---|---|---|

| mm | in. | µm | µin. |

| <0.203 | <0.008 | 0.5 | 20 |

| >0.203-<0.508 | >0.008-<0.020 | 0.8 | 32 |

| >0.508 | >0.020 | 1.0 | 40 |

Straightness

Out-of-straightness is defined as the maximum deviation from a straight-edge of a specified length. The following values apply:

| Strip width | Max. allowed deviation | ||

|---|---|---|---|

| mm | in. | mm/m | in./3 feet |

| >8-<20 | >0.315-<0.787 | 2.0 | 0.072 |

| >20-<50 | >0.787-<1.969 | 1.5 | 0.054 |

| >50-<125 | >1.969-<4.921 | 1.25 | 0.045 |

| >125 | >4.921 | 1.0 | 0.036 |

Mechanical properties

| Thickness | Tensile strength | ||

|---|---|---|---|

| mm | in. | MPa | ksi |

| <0.125 | <0.005 | 2100 | 305 |

| 0.125-<0.175 | 0.005-<0.007 | 2050 | 297 |

| 0.175-<0.225 | 0.007-<0.009 | 2000 | 290 |

| 0.225-<0.275 | 0.009-<0.011 | 1950 | 283 |

| 0.275-<0.375 | 0.011-<0.015 | 1900 | 276 |

| 0.375-<0.425 | 0.015-<0.017 | 1850 | 268 |

| 0.425-<0.475 | 0.017-<0.019 | 1800 | 261 |

| 0.475-<0.625 | 0.019-<0.025 | 1750 | 254 |

| 0.625-<0.825 | 0.025-<0.033 | 1700 | 247 |

| 0.825-<1.000 | 0.033-<0.039 | 1650 | 239 |

The proof strength (Rp0.2) is approximately 90% of the tensile strength (Rm). The manufacturing tolerance for tensile strength is ±80 MPa (±11.6 ksi.)

Fatigue strength

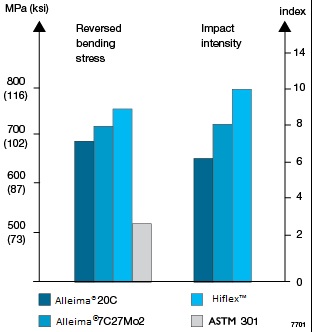

Alleima® 20C compressor valve steel has been used in the compressor industry for many years. The steel is tailored for applications requiring high fatigue strength. The fatigue strength depends on the surface and edge treatment of the material. The values presented are from none tumbled material with a smooth edge.

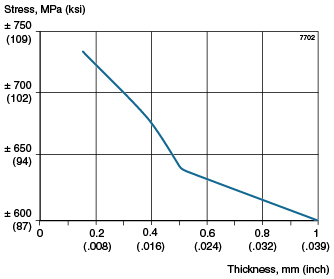

Reversed bending fatigue (mean stress = 0)

The fatigue strength of Alleima® 20C compressor valve steel in reversed bending is ±680 MPa (±99 ksi) at a failure probability of 5%. The value is valid for a strip thickness of 0.381 mm (.015 inch).

Figure 1. Reversed bending fatigue strength at a failure rate of 5%, as a function of the strip thickness in nominal tensile strengths.

Figure 1. Reversed bending fatigue strength at a failure rate of 5%, as a function of the strip thickness in nominal tensile strengths.

Fluctuating bending fatigue (minimum stress = 0)

Fluctuating bending fatigue strength for Alleima® 20C compressor valve steel has been calculated from reversed bending values. Goodmans formula gives 499±499 MPa ( ksi). Gerbers formula gives 608±608 MPa. The value is valid for a strip thickness of 0.381 mm (.015 in.).

Physical properties

Density, 7.8 g/cm3, 0.28 lb/in3

| At 20°C, W/(m °C) | 49 |

|---|---|

| At 68°F, Btu/(ft h °F) | 28 |

| Mean value for 50-100°C, J/(kg °C) | 460 |

|---|---|

| Mean value for 120-210°F, Btu/(lb °F) | 0.11 |

| Temperature | Temperature | ||

|---|---|---|---|

| °C | Per °C | °F | Per °F |

| 30-100 | 10.5 | 86-200 | 5.5 |

| 30-200 | 11.5 | 86-400 | 6.5 |

| 30-300 | 12.5 | 86-600 | 7.0 |

| MPa | 210000 |

|---|---|

| ksi | 30500 |

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.